To produce faster and better, you must innovate.

At Jamison Steel Rule Die we are constantly working to find new ways to lower costs and provide a better experience for our customers. One of the ways we accomplish this is by investing up to 1.5% of our revenue, annually, in research and development of new equipment, people and technologies.

This investment in R&D allows us to continue spot on accuracy in cutting, continue our speed in delivery of the final product and continue development of our teams.

Why is cutting die innovation important?

Cutting die innovation matters because the companies we work with don’t stop trying to find new and better ways to serve their customers. As they strive to exceed the needs of their customers – as their die partner – we too must strive to provide them with custom dies made to last to help them meet those goals. The only way to do that is to stay on top of the latest in equipment and technology which is why research and development are top priorities at Jamison.

Our Cutting Die Innovations Mean:

Increased longevity of die = lower total cost of ownership

Higher performing = more cuts, more cost effective

Less maintenance = more cost effective

Speed of delivery = client brings product to market faster

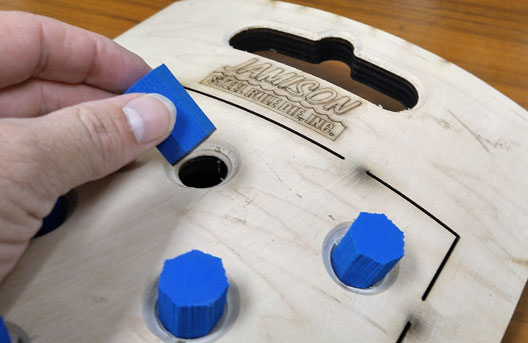

NO GLUE RUBBER

Our patent pending no glue ejection rubber pushes through a hole & locks into place on the die board, eliminating the safety hazard of superglue. Die cut operators can replace rubber on site mid run without glue, reducing repair time because dies do not have to be shipped out for re-rubbering.

Our no glue rubber can be used with any material, without distorting or dimpling. And, it lasts longer than glued ejection rubber, given that:

Glued rubber can compress up to 70%

No glue rubber compresses roughly 30%

HS3 – HIGH SPEED SURE STRIP

Our innovative HS3 cutting die uses our no-glue rubber system and ensures 100% strip of residual scrap — resulting in a cleaner finished product without dimpling.

HS3 runs up to 40% faster and requires less die pressure, dramatically reducing wear and tear on die cutting machinery and die ejection rubber.

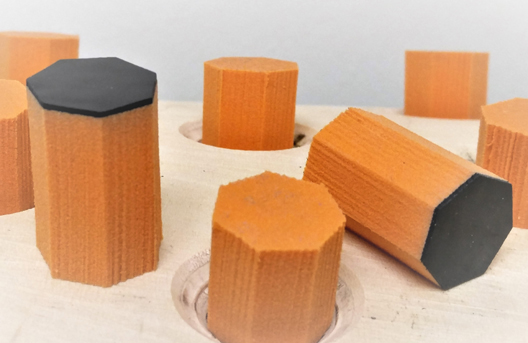

VENDOR BETA TESTING

As a trusted beta testing facility for many leading equipment and material manufacturers, we evaluate the latest die cutting technologies and processes like autobenders, new steel rule scoring profiles – rolling scores, dimpling paper with rubber, etc.

We use these advances in innovation to continually improve our die manufacturing capabilities and provide greater value for our customers.